Travelling Band Screens can screen large volumes of water meant for industrial use. This removes floating/suspended material that pose potential danger to downstream industrial equipment.

Travelling Band Screens consist of Basket frames fitted with screen meshes and arranged in a link chain system. The intake water flows through these baskets, with the debris left trapped behind in the baskets. The debris so collected is carried to the top by the revolving band screen. At the top, jets of water wash out the debris into a refuse disposal trench. Highly efficient spray nozzles fitted in the spray header pipe wash out the screening baskets. There is also the option of fitting an internal cleaning device for cleaning the spray nozzles of the spray header pipe.

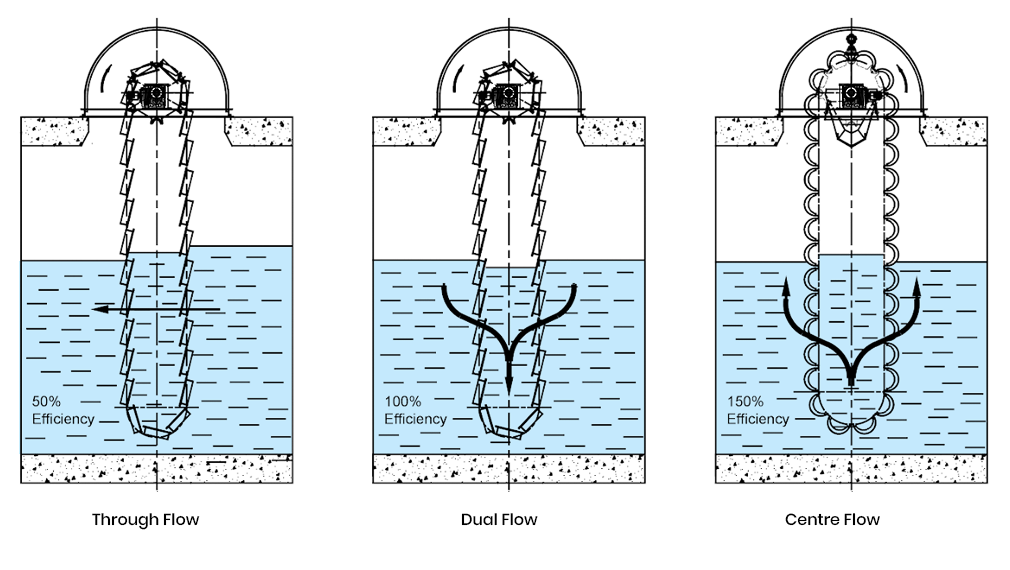

Travelling Band Screens are classified, depending on the pattern of water flow:

Through-Flow Band Screen

Water flows through the Through-Flow Band screens, effectively using 50% of the submerged mesh area. Mesh sizes range from 4 to 10 mm. The retained solids are discharged into a refuse trench.

Dual Flow Band Screen

Water flows from outside to the inside of the Dual-Flow Band screens, effectively using 100% of the submerged mesh area. Mesh sizes range from 4 to 10 mm. The retained solids are discharged into a refuse trench.

Centre Flow Band Screen

Water flows from inside to the outside of the Centre-Flow Band screens. The configuration of the baskets ensures 150% use of the submerged mesh area. Mesh sizes range from 0.1 to 10 mm. The retained solids are discharged into an internal collecting trough.

The water flow patterns enforced by the Dual Flow Band Screen and Centre Flow Screen ensure that debris is not carried over.

The Through-flow TBS and Dual-flow TBS have flat basket design whereas the Centre-flow TBS has a semi-circular basket design which ensures a much higher capacity for removing debris/trash. The baskets in Centre-flow TBS have a retaining plate, which gives this TBS the characteristics of a bucket elevator. The Centre-flow TBS takes the help of gravity for discharging much of the debris, thus requiring less back wash for its screens.

Centre-flow TBS can handle up to 1,00,000 m3 flow of water per hour with optimal filtering out of debris owing to its highly efficient screening capacity. A Centre-flow TBS also scores over the other two types of TBS by requiring less civil construction owing to its higher sump level.

The mesh size is determined by the quality of water required to be processed. Thus, to ensure screening out of tiny particles, fine mesh is used. In case of power utilities and desalination units, the mesh sizes are generally 1 mm to 2 mm. No further filtration is required to provide clear water for the plant.

We have supplied the largest Water Intake System in India consisting of 10 lines channeling 63,000 cu.m. to 82,000 cu.m. water to Coastal Gujarat Power Ltd. We have also supplied one of the largest intake systems in the country, consisting of 6 channels of 55000 cu.m per hour and 2 channels of 8000 cu.m per hour for Nuclear Power Corporation.

The first Centre flow Band Screen operating in India was supplied for a capacity of 25,000 cu.m per hour with 2 mm screen opening. In Europe and other developed nations, Centre flow type Travelling Band Screens are more commonly used than the other two type of screens because of the efficiency and ease of operation. Centre-flow Band Screens are also environmentally friendly, as they can be designed for fish recovery. Fishes are segregated from the debris through low pressure water jets and channeled to a separate trough for disposal.