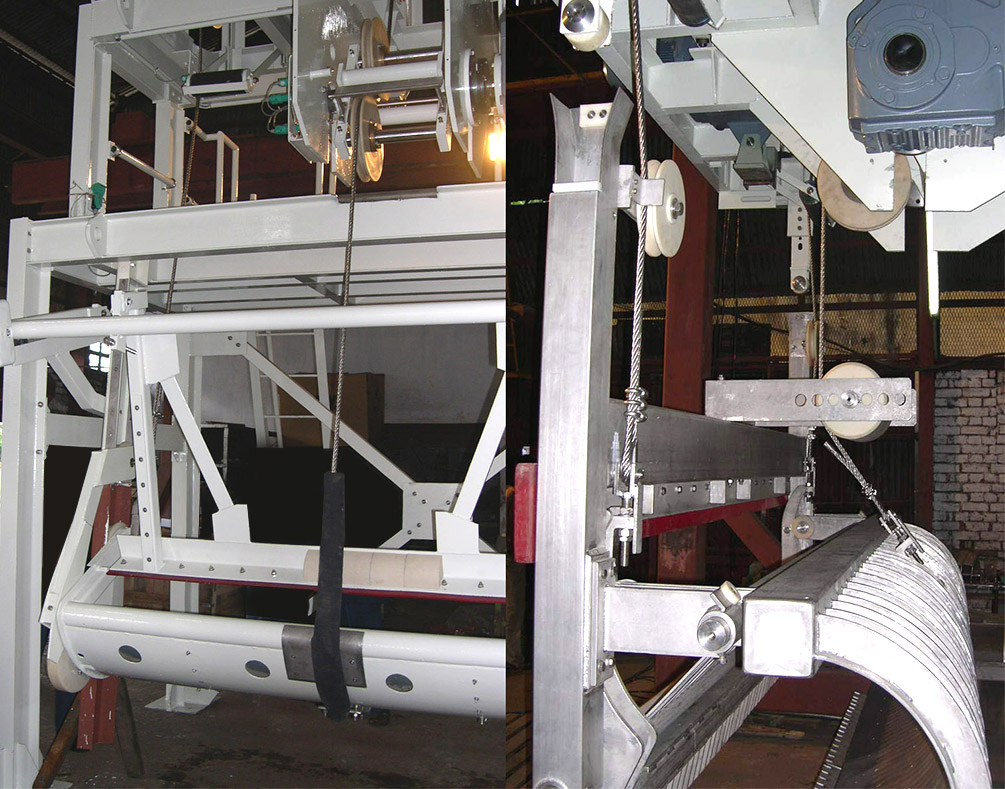

A manual/automatic bar screen cleaner mechanically cleans out bar screens with the help of a grab carriage having anti-wedging design. The grab carriage runs on guide channels which are fixed to the concrete walls below the floor level. The channels run from the sump base up to the top of the discharge point. Multiple channels can be cleaned by a mobile bar cleaner moving on rails.

The grab travels down in an open position. When it meets an obstruction or reaches the bottom of the chamber, it closes automatically (using a slack cable mechanism). It then travels upwards with the collected debris and discharges it on a conveyor or waste collector.

Necessary safety switches and alarms are provided to detect slackness of rope, open/close status of grab to enable automatic operation of the cleaner.

The mobile version of the cleaner can be stationed by means of proximity switches at the channel requiring cleaning.

There are three versions of cable operated bar screen cleaners:

- Fixed type (which cleans individual channels)

- Mobile type (which can clean multiple channels)

- Portal Track type (also meant for cleaning multiple channels)

The online cleaning of bar screens by the cleaner allows screening of the incoming water to continue without any interruption.

Salient features of these cleaners are:

- High cleaning efficiency

- Drive parts are installed on the operating floor

- No moving parts are in contact with water

- Plastic rollers for grab movement

- Individual, adjustable hoisting ropes

- Separate drives for hoisting and tilting

- No recess inside pier walls